April’s machine of the month is a labelling system built for a leading toiletry manufacturer. The solution was designed to apply front and back labels onto shaped toiletry bottles with a high level of accuracy and uniformity. It was installed directly into the customer’s filling line and capable of labelling more than 60 bottles per minute. The machine was…

March’s machine of the month is an ALline linear labelling system built for a producer of fruit juices. The customer required a system to apply front and back product labels to their juice bottles at 170 bpm. The machine was to be placed on their new filling line, with the priority to maximise performance and minimise downtime, optimising productivity….

Our latest D-wrap tray labelling machine with integrated promo labeller, also known as ‘full wrap’ labelling (providing a result almost equivalent to a sleeve), features two in-series labelling heads for non-stop operation, minimising line downtime and maximising efficiency. #automation #foodpackaging #foodindustry #foodmanufacturing #labelling #meatprocessing #meatindustry #packaginginnovation

When it comes to streamlining your packaging line with efficiency and precision, selecting the right label applicator is crucial. Whether you’re a small artisan producer or a large-scale manufacturing powerhouse, the correct label applicator can significantly impact your product’s marketability and your brand’s reputation. Here’s how to make the best choice for your needs, and why ALTech UK stands…

May’s machine of the month is a labelling head built for a Vertical Form, Fill and Seal (VFFS) machine manufacturer. The end user of this solution was a fresh produce supplier, who required a system to apply relatively large labels onto their bags during the packaging process. This allowed them to tailor their packaging to the individual products, reducing…

November’s machine of the month is a non-stop pouch/bag labelling system provided by multiple ALritma S labelling heads installed into a major producer of pharmaceutical products. Ten labelling heads were integrated into their new multi-line packaging machine to apply multi-page booklets onto the top of painkiller bags. The configuration of the line would not allow it to be stopped…

October’s machine of this month is a top and side wrap labelling system built for a major producer of ready to eat salads / sandwich fillers in Northern Europe. The customer required a ‘watchstrap’ application; in this instance, the label is applied into a recess on the lid of the product, then wrapped onto the side to provide both…

ALTech UK have designed and installed a high volume sachet labelling solution for Montagne Jeunesse, a major manufacturer of beauty products such as face masks and scrubs. The machine has been installed for over 12 months and currently labels more than 750,000 sachets per month. The system has proved to be robust, accurate and reliable, requiring only the renewal…

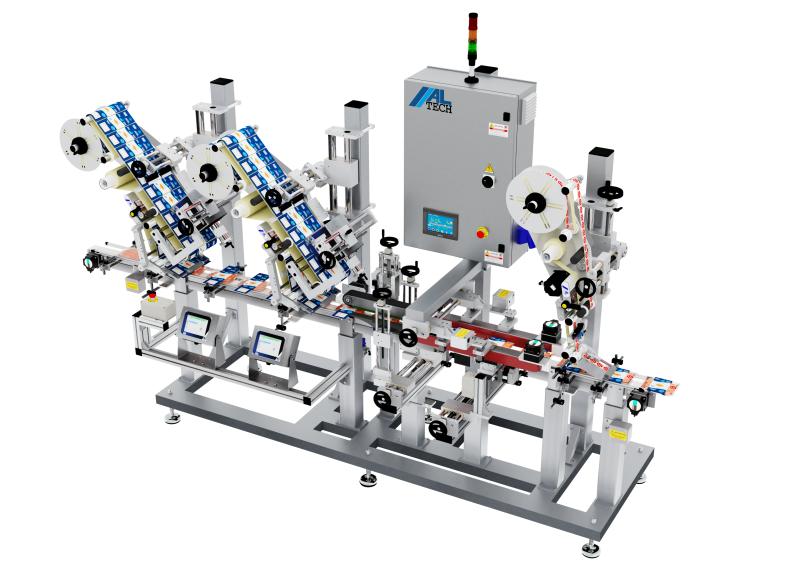

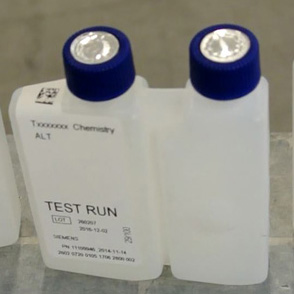

September’s machine of the month is an ALline Special system for a market leading producer of pharmaceutical and diagnostic products, designed to print and apply labels to the sides of specialist twin closure bottles. This application required the label to be bent around the top of the product and follow the contour of the bottle to ensure the 2D…

August’s machine of the month is an ALline C built for Groupe Le Graёt, an important French producer of preserves and jellies. The machine was required to label glass jars at a rate of over 180 products per minute with the flexibility to apply a variety of labels, from a simple partial wrap label to a full wrap body…