Thank you for contacting us, we will respond to your enquiry as soon as possible.

Required fields are missing. Please check that ALL fields marked with * are properly filled in.

You Enquiry is currently being sent.

There was an error sending your message. Please check to ensure ALL required fields are filled in and correct then try again. If this persists then please Contact the webmaster.

Required fields are missing. Please check that ALL fields marked with * are properly filled in.

Thank you for requesting a quotation from us. We endeavour to process quotation requests within 24 hours during normal working hours.

You Enquiry is currently being sent.

There was an error sending your message. Please check to ensure ALL required fields are filled in and correct then try again. If this persists then please Contact the webmaster.

There was an error logging in. Please check your username and password.

Success you are now logged in.

Please Wait

There was an error logging in. Please check your username and password.

ALwrap is a desktop wraparound labelling machine which was developed specifically for applications requiring an economical, but accurate cylindrical product labelling system for products ranging from 14mm to 130mm standard; to be labelled with labels up to 200mm in height on the product, making it one of the most flexible machines of its type available on the market.

Key to this flexibility is its three roller application system, pinching the product accurately between two lower and one upper roller to ensure smooth and accurate rotation as the label is fed on to the product, even with small diameter and/or light products.

ALwrap includes a powerful LCD controller, allowing setting of all the labelling parameters electronically, including the ability to apply two labels per product 'front-back' in a single product placement if required. Once set, product setup 'recipes' can be stored and recalled between products and the controller includes many useful functions such as a labelled product counter etc.

Where a label is required to be applied into a recess, ALwrap has the functionality to proportionally reduce the dispensing speed as compared to the product rotation speed so as to match the real rotation speed of the recessed area: an advanced control function very few other semi automated machines feature, instead relying on crude o-rings etc on the rollers to space the product because the feed speed is fixed to the rotation speed.

ALwrap is extremely easy to load and operate; only rotating the product when the third roller unit is placed down on the product rather than rotating continuously like many machines which can make the machine difficult to load. Adjustment between products is completed by easy to move slide systems, with a typical label application speed of less than 2 seconds with most products.

ALwrap with TIJ Coding Printer

ALwrap with TIJ Coding Printer

Recessed Label Panel Gin Bottle

Recessed Label Panel Gin Bottle

Sensor Registration to Cap

Sensor Registration to Cap

Desktop Tamper to Body Registration

Desktop Tamper to Body Registration

ALwrap with SATO CL4NX Printer

ALwrap with SATO CL4NX Printer

Epson C6500 Colour Printer/ALwrap 300mm

Epson C6500 Colour Printer/ALwrap 300mm

ALwrap with Mini Jars (1oz)

ALwrap with Mini Jars (1oz)

Tubes with Lip

Tubes with Lip

Integrated Tamper Label Desktop Jars

Integrated Tamper Label Desktop Jars

Desktop Small Tube Labelling System

Desktop Small Tube Labelling System

ALwrap with Small Bottles

ALwrap with Small Bottles

Syrup Bottles with Laser Positioning Device

Syrup Bottles with Laser Positioning Device

Matrix Left In Labels (Colour Printers)

Matrix Left In Labels (Colour Printers)

Desktop Beer Can Labelling

Desktop Beer Can Labelling

ALwrap with E-Liquid Small Bottles

ALwrap with E-Liquid Small Bottles

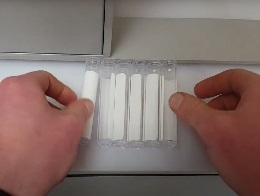

ALwrap with Syringes

ALwrap with Syringes

ALwrap with Honey Jars

ALwrap with Honey Jars

ALwrap with Ribbon Save TT Printer

ALwrap with Ribbon Save TT Printer

Transparent Labels - Clear-on-Clear

Transparent Labels - Clear-on-Clear

Small Diameter Syringe with Direct Feed Printer

Small Diameter Syringe with Direct Feed Printer

Desktop Paint Can Labelling

Desktop Paint Can Labelling

Contact ALTech UK to discuss your requirements with our experienced and knowledgeable team.

Contact UsContact ALTech UK to discuss your requirements with our experienced and knowledgeable team.

Contact UsContact ALTech UK to discuss your requirements with our experienced and knowledgeable team.

Contact Us